[[{“value”:”

[[{“value”:”

A Nikkei report spells bad news for anyone hoping that prices of electronic devices won’t go up this year. A critical component in many products with advanced chips in them is in short supply.

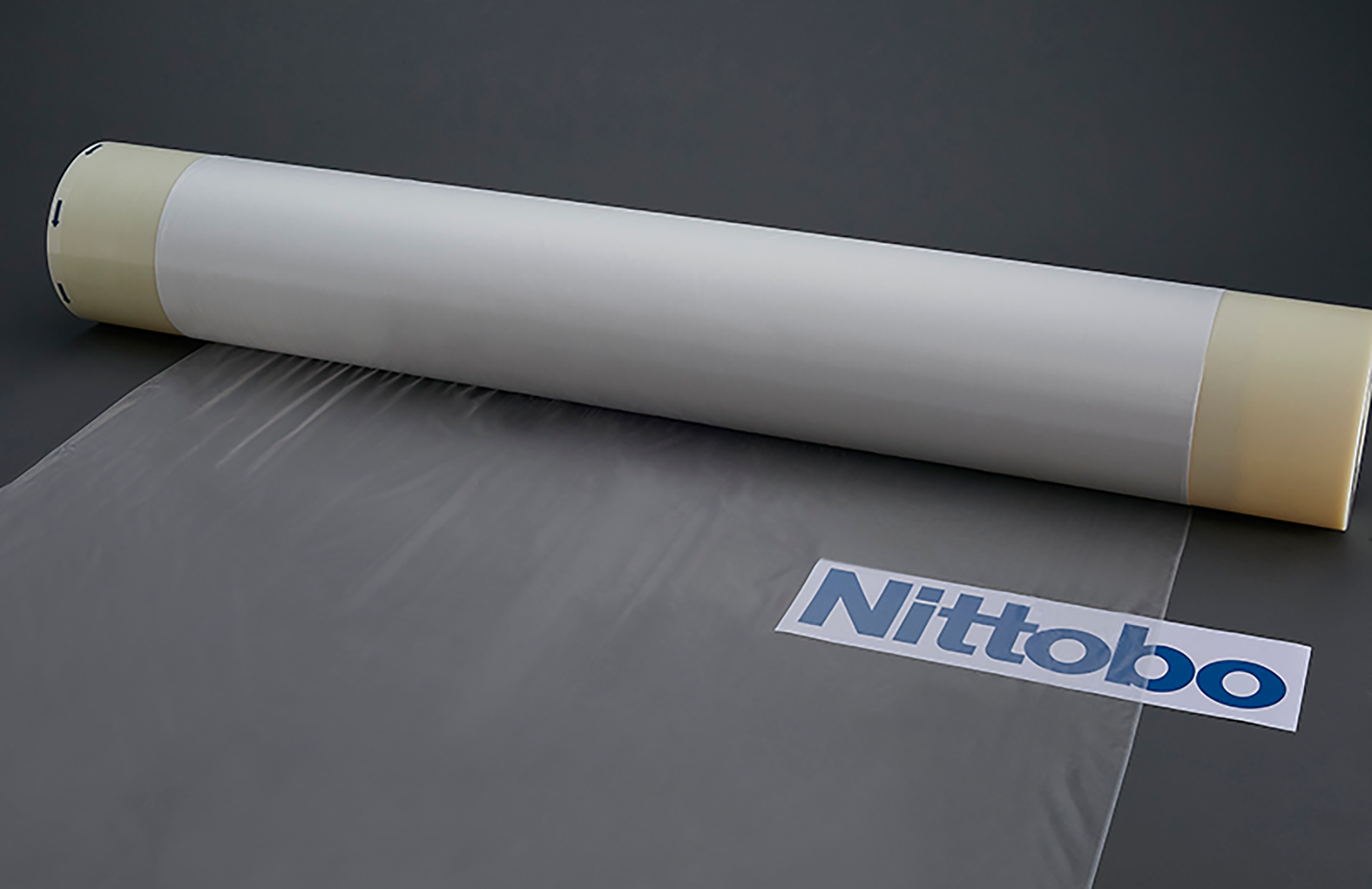

The material is called “glass cloth” and it is an important component in a particular type of substrate (essentially a little pad that the chip is mounted on to attach it to the circuit board). There aren’t may companies that make it at a high quality level and high volume. There’s essentially only one major supplier: the Japanese company Nitto Boseki, or Nittobo.

Many companies mount their chips on what is called a BT substrate (bismaleimide triazine), a small connecting base mounting pad that has particularly good properties for electric conductivity, heat resistance, and stiffness. The chip, on the BT substrate, is then mounted on the PCB (Printed Circuit Board).

Apple uses this process in nearly everything it makes, but so do a lot of other tech companies, including Broadcom, Nvidia, AMD, Qualcomm, and many more.

The problem is this: With the rise of AI chips, companies need more glass cloth, but as Nikkei reports, Nittobo is struggling to keep up with demand since no other company manufactures it in volume. So the entire high-end chip industry, for everything from mobile products to AI servers, is fighting over this limited supply. Nittobo is expanding, but the new capacity reportedly won’t be ready until later in 2027.

Nikkei reports that Apple is exploring other solutions, including sending some of its own employees to a small glass fiber maker called Grace Fabric Technology to try to get them to improve the quality to the level Apple needs. Apple and all the other tech giants are also looking at possible other chip packaging solutions that won’t suffer from this bottleneck.

This is just one of several supply problems caused by a boom in AI servers and data centers of late. The ongoing RAM shortage has been well-documented, but there are issues with all sorts of downstream supply chain parts, from particular rare earth materials to specialized drill bits used to make PCBs. The wealthiest companies in the world are paying whatever it takes to secure the limited supply of what they need to make more products, and those costs are sure to be passed on to the consumer in one way or another.

“}]]

This Post Has 0 Comments